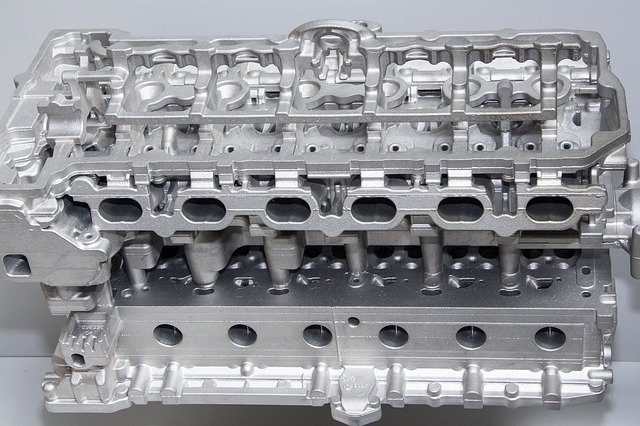

Best Quality Cylinder Heads, Engines, Turbos and Gearboxes

Remanufactured Quality Cylinder Heads, Engines, Turbos and Gearboxes

Bridge is a supplier of Quality Cylinder Heads, Engines, Turbochargers and Gearboxes for various makes of vehicles through our production supply. On those rare occasions that we are unable to fulfil your enquiry with one of our stock or production engine/turbo/cylinder head units, then we offer a Customer Own Unit rebuild (COU).

Our sales team will be able to discuss your requirement and offer you an all-inclusive price to rework/re-build your engine/turbo or cylinder head back to a standard that you would associate with all Bridge’s products. You can be rest assured that the returned product comes with the same 12 month unlimited mileage warranty as all our remanufactured units.

There is a comprehensive stock to ensure first class customer service with minimum vehicle down time. We offer free next day delivery throughout UK mainland on many stock items.

We will arrange for a carrier to collect the unit for rework/rebuild. As long as the unit is in re-workable condition then a quick turnaround time will ensure the vehicle is quickly back on the road.

Bridge is a trading name of Chase Engines Ltd and is equipped to remanufacture all OEM diesel and petrol cylinder heads and engines, both classic and modern, and along with our industry partners gearboxes, turbochargers and engines.

All of our products are remanufactured to the highest specification and supplied, where requested, with ancillary items to ensure trouble free installation.